Forklift safety tips for large warehouses

|

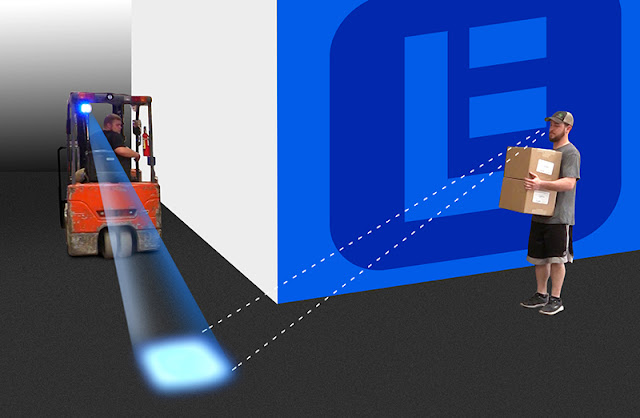

| Forklift safety light |

Forklifts are arguably the single most

important piece of equipment in any given warehouse and its importance only

increases as the size of the warehouse also continues to grow. In fact most

experts agree than a single forklift can perform tasks that would take 10 to 15

workers to complete if they were to do it manually. This underlines just how

important the forklift has become in the workplace. But using forklifts is not

entirely risk free and there exists serious risk of injury and damages if

safety precautions are not in place when using the forklifts. There are many

ways to increase forklift safety in the warehouse but the most effective ones

include the following.

Regular

maintenance

Make sure that the forklifts are always in

proper working order by carrying out scheduled maintenance on a regular basis.

You might not necessarily have to inspect the forklifts on a daily basis but a

maintenance schedule that ensures they are inspected at least once every week

should keep them in relatively good working order.

Operational

safety

When using a forklift, it is important for

the operator to be able to see the surroundings and therefore a forklift camera

system is important. The forklift camera allows the operators to see around

obstacles and avoid any mishaps that may happen by accident. A wireless

forklift camera, on the other hand, allows operators to work the forklifts

remotely without any risks. In addition to the cameras, it is also important to

have the property lighting for safety. A red zone forklift light, for instance, warns operators when they are entering

areas of the warehouse where they need to be more careful. The warning lights

can alert the operators of any impending dangers and help them avoid the same

or move out of the way in good time.

Comments

Post a Comment